Cider Production

Cider Production: A History

Explicitly, Cider Production in its rudimentary form has existed in England since the Celtic era. Markedly, the Romans are widely accredited with introducing orchard cultivation on a larger scale to England. Meanwhile, in the 21st Century, cider production and the techniques and processes involved in crushing, pressing, and fermenting the apple (or pear) have come a long way.

Cider Production: The Modern Era

Specifically, filtration media has become a critical part of the process in cider production for many manufacturers. Generally speaking, the majority of manufacturers are constantly looking for ways to preserve the flavour of the final product. Notwithstanding trying to reduce the overall cider production costs. This can be achieved through introducing filtration in the brewery and process.

This ultimately results in the following:

- Lower Cider Production Costs

- Minimises Beverage Loss

- Improve Water & Energy Consumption

- Improve the Products Shelf Life

- Removes Spoilage Organisms, Haze from Polyphenols, Controlling Yeast Levels

Nevertheless, the old methods and traditions still stand the test of time and are often preferred to these newer methods.

Application

Regardless of whether old or new methods are preferred in the fermentation process, there are other ways of reducing costs. One way to reduce operational costs in cider production is through the incorporation of a suitable water softener system. A suitable softener can supply a consistent supply of softened water which can further improve water and energy consumption.

Softened water is often used in the ‘Washing’ process which takes place before heavy machinery is involved in the production process. Washing is important as it removes bacteria and residue from the apples. Having clean water is a clear and obvious requirement for this stage, so softened water is a minimum requirement. Additives are often added between pressing and maturation which stop spoilage.

System Commissioning

Puretech Water Systems (UK) Ltd supply such a system to a cider manufacturer based in Northamptonshire. The system is used to supply up to 15m 3 over a 24-hour period for the brewing and cleaning processes.

A 60-litre duplex softener system meets this particular clients’ requirements.

The installation we undertook utilises a Raw Water Break Tank with an integrated air gap. This provides a buffer for supply to the water softener which helps to ensure the plant always has a high enough flow of water when required. Water is drawn from the Raw Water Break Tank by a floor mounted booster pump with sufficient pressure controls.

Reducing Operation Costs

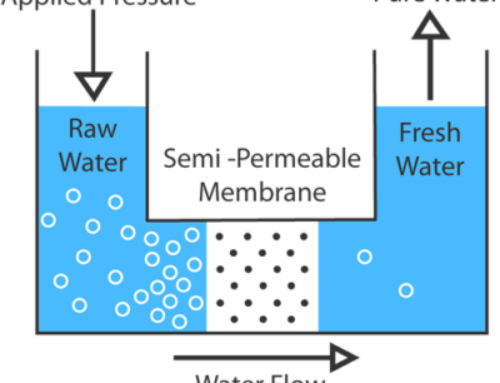

Any treated water used in the pressing, blending, and settling processes should have low alkalinity and a low mineral content. Reverse Osmosis water or similarly treated water would be applicable for this.

Reducing the operational costs in production by improving efficiencies is a sensible measure for any business to take. The energy costs of running and operating a steam boiler can be reduced through good water treatment.

The blowdown periods for the boiler and a reduction in chemical costs are the positives that can be achieved with good water pre-treatment. Once again, water softening plants and reverse osmosis plants can provide a viable solution.

If you have any water treatment requirements similar to those mentioned in this blog post, please do not hesitate to contact us to find out more information. We appreciate that every business is different with unique goals.

Find Out More

Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. We work across multiple sectors providing water processing solutions.

Interested in finding out more about the water softener services and systems we provide?

Find more information here: https://puretechsystems.co.uk/industrial-water-softeners/