Reverse Osmosis Plants to the Printing Industry

Puretech Water Systems (UK) Ltd offers a wide range of reverse osmosis plants to the Printing Industry.

Owing to the fact that printing utilises a lot of water in its processes, a consistent supply is obligatory. In any case, the main ingredient within a dampening solution is water, something that is routinely used in printing.

Comparatively, overly soft water leads to emulsification. Equally, exceedingly high amounts of hard water cause deposits that damage the blankets and ink rollers that are used in the printing process.

The Solution

It is important to realise the affect poor water quality can have when printing. Undoubtedly the negative impact it has on the appearance of the final printed product is undesirable.

At any rate, securing a high-grade water supply facilitates generating the dampening solution whilst equally matching it to the printing process. Furthermore, it is important to note that the dampening solution counteracts the issues found with incorrect water hardness levels. Establishing that these processes run in parallel from the beginning avoid otherwise needless problems in development.

Conclusion

Besides the fact that a reverse osmosis plant improves the quality of the finished product, it enables cost saving exercises elsewhere. Another key point to raise is the resultant reduction in the amount of alcohol and additives used in the production process. Overall, resulting in savings costs whilst improving the quality of the printing.

Our System

What is a Water Softener?

A water softener is used to remove hardness from the incoming towns mains water supply.

For instance, this is achieved by removing the calcium and magnesium ions. These ions would otherwise cause scaling within a water system. Scaling can present itself in many ways.

Below is a list of the most common effects of scaling;

- Water heaters scaling impedes on their ability to heat water efficiently.

- Scaling on glassware such as shower screens and glasses is unhygienic and cosmetically unappealing.

- The scaling on tap outlets and scale build up within water holding tanks can have detrimental effects on systems.

Water softeners remove the calcium and magnesium ions and traps them on its filter surface which acts as a magnet.

Therefore, we exchange these calcium and magnesium ions for sodium ions which, in turn, creates softened water. Summing up, this results in water ready for consumption.

Find Out More

Chiefly, Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. Consequently, Puretech Water Systems (UK) Ltd work across multiple sectors providing water processing solutions.

Interested? Find out more about water softening systems with Puretech Water Systems (UK) Ltd.

Find more information here: https://puretechsystems.co.uk/water-softeners-explained/

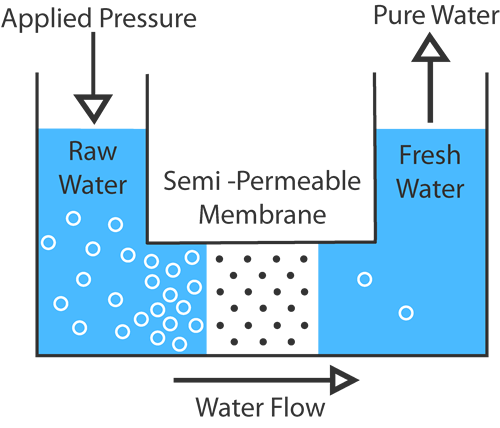

How does Reverse Osmosis work?

Reverse Osmosis is a high-pressure water process which forces water to be treated through a semi permeable reverse osmosis membrane. So, the membrane has two outlet channels. One being the permeate water (Purified) which passes the heavily filtered water onto the point of use application. This purified water typically has around 98% of the incoming contaminants removed, such as dissolved salts, bacteria, organics and pyrogens.

On the other hand, the other outlet is where the rejected water (Concentrate) is sent directly to drain.

In some cases, this concentrate water can be re-circulated back to the front of the reverse osmosis plant and re-processed. In conclusion, this particular process can significantly reduce water wastage.

Find Out More

Chiefly, Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. Consequently, Puretech Water Systems (UK) Ltd work across multiple sectors providing water processing solutions.

Interested? Find out more about reverse osmosis systems with Puretech Water Systems (UK) Ltd.

Find more information here: https://puretechsystems.co.uk/what-is-reverse-osmosis/

Benefits of Reverse Osmosis Water Systems