Distillery Systems

Significantly, Puretech Water Systems (UK) Ltd has worked at various production facilities in the beverage industry over the years. For one thing, distilleries have a requirement for a good grade of pure water to assist with their production processes.

In fact, we are suppliers to several distilleries, and we have been for nearly a decade. Chiefly, installing and maintaining various reverse osmosis plants which are used to dilute the distilleries spirits to the required strength. Consequently, when diluted with pure water, the final product does not look cloudy and the products presentation is not compromised.

The Solution

In the light of this, we have assisted distilleries who were obtaining poor results when using basic filtration processes for alcohol dilution. So as to address this, our team build bespoke installations to suit the needs of each distilleries production facility. Henceforth, we highly value site visitations at distilleries. Markedly, it aids us in being able to establish the correct specification for each unique facility. In particular, it is important to understand that a distilleries specification differs from facility to facility.

Conclusion

Subsequently, noticeable improvements are instantly recognisable for the production facility. In summary this results in a consistent grade of pure water for distilleries and their manufacturing process.

In addition to our own plants, we also maintain many other existing reverse osmosis plants, together with water softeners, for distilleries. Above all, we understand that getting the right water quality is very important in achieving a polished finished product.

Our System

What is a Water Softener?

A water softener is used to remove hardness from the incoming towns mains water supply.

For instance, this is achieved by removing the calcium and magnesium ions. These ions would otherwise cause scaling within a water system. Scaling can present itself in many ways.

Below is a list of the most common effects of scaling;

- Water heaters scaling impedes on their ability to heat water efficiently.

- Scaling on glassware such as shower screens and glasses is unhygienic and cosmetically unappealing.

- The scaling on tap outlets and scale build up within water holding tanks can have detrimental effects on systems.

Water softeners remove the calcium and magnesium ions and traps them on its filter surface which acts as a magnet.

Therefore, we exchange these calcium and magnesium ions for sodium ions which, in turn, creates softened water. Summing up, this results in water ready for consumption.

Find Out More

Chiefly, Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. Consequently, Puretech Water Systems (UK) Ltd work across multiple sectors providing water processing solutions.

Interested? Find out more about water softening systems with Puretech Water Systems (UK) Ltd.

Find more information here: https://puretechsystems.co.uk/water-softeners-explained/

How does Reverse Osmosis work?

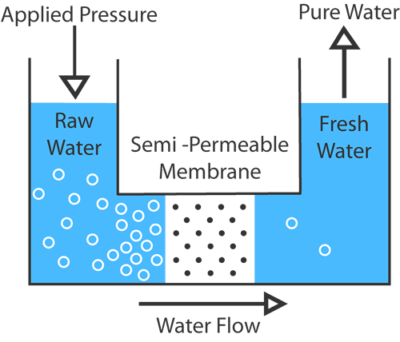

Reverse Osmosis is a high-pressure water process which forces water to be treated through a semi permeable reverse osmosis membrane. So, the membrane has two outlet channels. One being the permeate water (Purified) which passes the heavily filtered water onto the point of use application. This purified water typically has around 98% of the incoming contaminants removed, such as dissolved salts, bacteria, organics and pyrogens.

On the other hand, the other outlet is where the rejected water (Concentrate) is sent directly to drain.

In some cases, this concentrate water can be re-circulated back to the front of the reverse osmosis plant and re-processed. In conclusion, this particular process can significantly reduce water wastage.

Find Out More

Chiefly, Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. Consequently, Puretech Water Systems (UK) Ltd work across multiple sectors providing water processing solutions.

Interested? Find out more about reverse osmosis systems with Puretech Water Systems (UK) Ltd.

Find more information here: https://puretechsystems.co.uk/what-is-reverse-osmosis/

Benefits of Reverse Osmosis Water Systems