Industrial Reverse Osmosis Oxfordshire

Puretech Water Systems (UK) Ltd offers a wide range of industrial Reverse Osmosis (RO) water systems capable of handling industrial flow rates.

The Industrial Reverse Osmosis Water System Solution

Industrial RO Systems are required to remove impurities from the water on a molecular level. Industrial Reverse Osmosis is prevalent in numerous industries as part of multiple manufacturing processes. It is also commonly used as a measure to drastically improve energy efficiencies by improving feedwater quality.

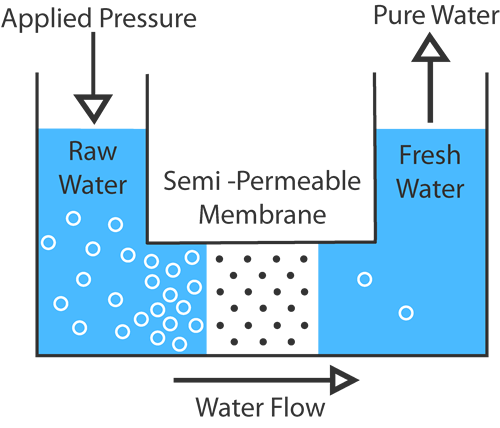

Reverse Osmosis (RO) is a water purification technology that uses semipermeable membranes to remove ions, molecules and particles from water.

The membrane has two outlet channels. One is the permeate water (Purified Water) which passes the heavily filtered water onto the point of use application. Usually, this purified water has had around 98% of the incoming water contaminants removed from it.

On the other hand, the other outlet is where the rejected water (Concentrate) is sent directly to drain. In some cases, this concentrate water can be re-circulated back to the front of the reverse osmosis plant and re-processed. In conclusion, this particular process can significantly reduce water wastage.

Pre-Treatment is required to protect and prolong the life of the sensitive filtration media that is used in industrial reverse osmosis. Usually, this protection is required from the chemicals that are typically found in the towns mains water supply. Forthwith, this protection typically comes in the form of water softeners and carbon filters.

An Industrial RO System is used to obtain a specific grade of water ideal for blending, washing or sterilising in industrial processes. Usually, this is from the incoming towns mains / bore hole potable water supply.

An Overview of How Industrial RO Works

Applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential differences of the solvent, a thermodynamic parameter.

Reverse Osmosis removes dissolved and suspended solids from water, including bacteria.

The solute is retained on the pressurized side of the membrane and the pure solvent can pass through. The membrane technologies prevents large molecules or ions through the pores. However, the membrane allows smaller components of the solution (such as solvent molecules) to pass freely.

In the normal osmosis process, the solvent naturally moves from an area of low solute concentration (high water potential), passed through the membrane, to an area of high solute concentration (low water potential).

The driving force for the movement of the solvent is the reduction in the free energy of the system. This occurs when the difference in solvent concentration on either side of a membrane is reduced. By doing this, we generate osmotic pressure due to the solvent moving into the more concentrated solution.

When we apply an external high pressure to reverse the natural flow of pure solvent, it is known as, reverse osmosis.

Because reverse osmosis also involves diffusion it makes the process dependent on pressure, flow rate, and other conditions.

In conclusion, reverse osmosis is most known for its use in water purification systems. Because it aids in reducing the conductivity levels in the water and can provide a high grade of water purity.

What Sectors Can RO Be Used In?

Water is required in most manufacturing applications, it can be used to clean other machinery, process parts, produce consumables, wash out packaging before products are inserted and more.

These are the industries/sectors that we specialise in providing RO systems:

Our Industrial Reverse Osmosis Systems

Installation and Servicing Industrial Reverse Osmosis Systems

A Summary - Industrial Reverse Osmosis Systems

Certainly, an Industrial RO unit is considered essential equipment for many different industries for process water. You can see the 16 different industries we have experience supplying to via in the section above or by our “Industry” drop down menu tab. Markedly, all of the industries we work in have complex requirements and varying end use applications. Undeniably, each industry and each application requires specific pure water quality demands in order to meet production needs. Without a doubt, a reliable, cost effective and consistent water supply is imperative to most industrial operations. Henceforth, we specialise in providing tailored water treatment solutions that meet these exacting requirements.

Installation & Servicing Industrial Reverse Osmosis Systems

A large number of commercial facilities require Industrial Reverse Osmosis Systems in their day to day operations. Typically, industries use reverse osmosis water in their production processes or to drastically reduce energy costs. Improving efficiencies by ensuring that water is appropriately pre-treated. Puretech Water Systems (UK) Ltd stock, supply, provide full installation and commissioning whilst also offering full maintenance services on these systems.

Altogether our experienced in-house service and installation team are proficient in carrying out maintenance, installation and breakdown repairs. In truth, as a company, we work on a wide variety of water treatment plants as well as our own plants.

Without a doubt, our business has been built around creating and maintaining strong working relationships with our customers. To this end, we believe firmly forged transparent relationships and great service are fundamental to being a reputable service provider.

Be it aquatics, cosmetics, healthcare, horticulture, industrial or pharmaceutical, Puretech Water Systems (UK) Ltd has the solution.

Find out more

Chiefly, Puretech Water Systems (UK) Ltd specialise in water treatment and process filtration. Consequently, Puretech Water Systems (UK) Ltd work across multiple sectors providing water processing solutions.

Interested? Find out more about reverse osmosis systems with Puretech Water Systems (UK) Ltd.

Find more information here: https://puretechsystems.co.uk/what-is-reverse-osmosis/

Benefits of Industrial Reverse Osmosis Water Systems